About this deal

By contrast, polyester resins are usually made available in a 'promoted' form, such that the progress of previously-mixed resins from liquid to solid is already underway, albeit very slowly. The only variable available to the user is to change the rate of this process using a catalyst, often Methyl-Ethyl-Ketone-Peroxide ( MEKP), which is very toxic. The presence of the catalyst in the final product actually detracts from the desirable properties, so that small amounts of catalyst are preferable, so long as the hardening proceeds at an acceptable pace. The rate of cure of polyesters can therefore be controlled by the amount and type of catalyst as well as by the temperature. Here are the best glue for all kinds of plastic and many of them strongly bind other materials too.

Epoxy coatings are often used in industrial and automotive applications since they are more heat resistant than latex-based and alkyd-based paints. Epoxy paints tend to deteriorate, known as "chalking out", due to UV exposure. [40] Epoxy coatings have also been used in drinking water applications. [41] Epoxy resins may be reacted ( cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (sometimes called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Epoxy is a two-part adhesive made up of epoxy polymer and hardener. After mixing, it creates an extremely durable bond. Epoxy glue for plastic also fills gaps, and won’t shrink when exposed to different temperatures. Its structural strength can withstand heavy loads as well as drilling. The key to using glue with plastics is finding the right combination. That means first and foremost, you need to know what kind of plastic you’re dealing with.Sinha, Animesh; Islam Khan, Nazrul; Das, Subhankar; Zhang, Jiawei; Halder, Sudipta (2017-12-18). "Effect of reactive and non-reactive diluents on thermal and mechanical properties of epoxy resin". High Performance Polymers. 30 (10): 1159–1168. doi: 10.1177/0954008317743307. ISSN 0954-0083. S2CID 104235230.

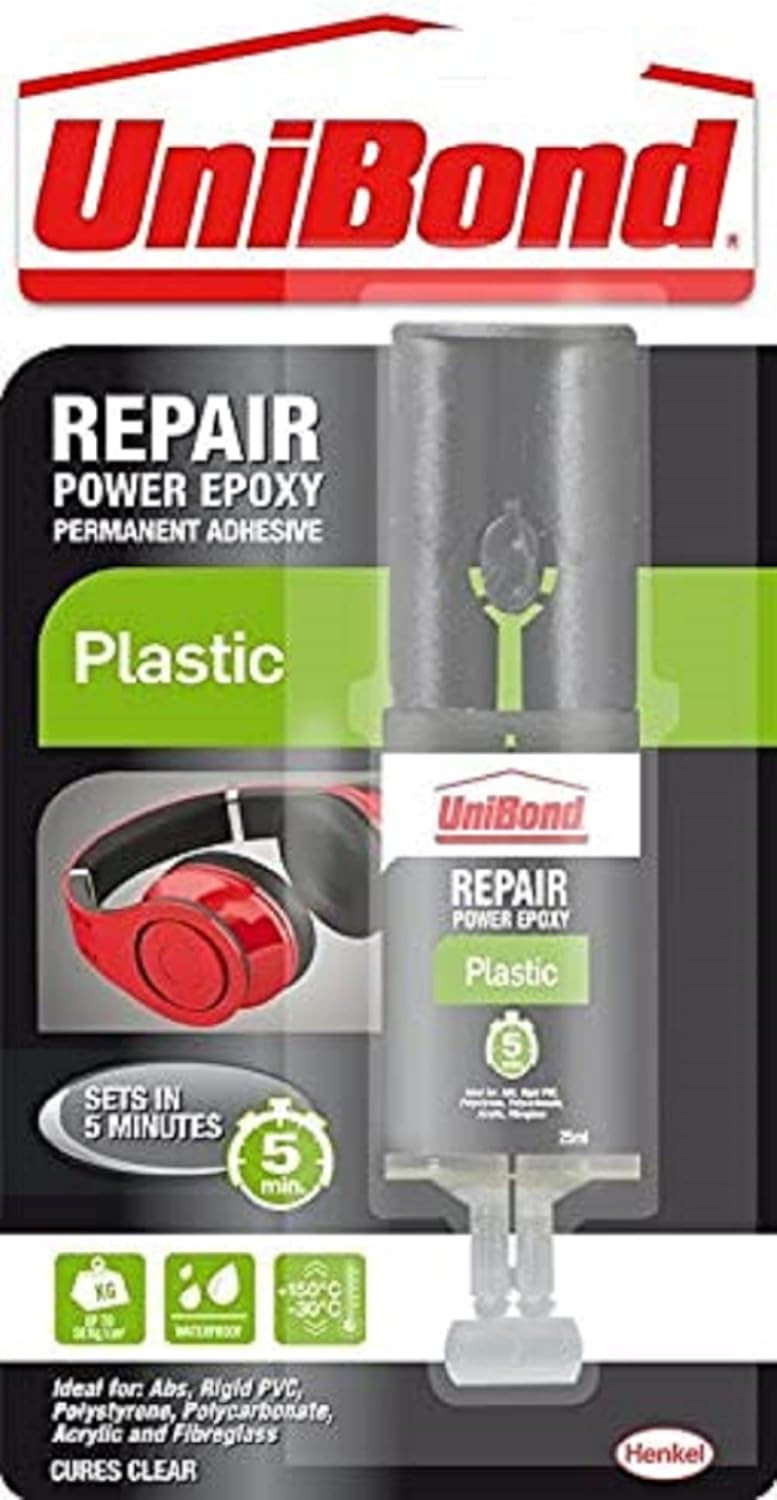

Monte, Salvatore J. (1998), Pritchard, Geoffrey (ed.), "Diluents and viscosity modifiers for epoxy resins", Plastics Additives: An A-Z reference, Polymer Science and Technology Series, Dordrecht: Springer Netherlands, vol.1, pp.211–216, doi: 10.1007/978-94-011-5862-6_24, ISBN 978-94-011-5862-6 , retrieved 2022-03-09 Epoxy homopolymerisation is often used when there is a requirement for UV curing, since cationic UV catalysts may be employed (e.g. for UV coatings). The Super Glue Plastic Fusion Epoxy Adhesive “is the best glue for plastic I have ever encountered,” according to one buyer. Although epoxy adhesives like this one require mixing, the syringe can simultaneously dispenseequal parts of the product for the most accurate and simple preparation. Once applied the product takes five to 10 minutes to set and then 24 hours to fully cure. May, Clayton (2018). Epoxy Resins: Chemistry and Technology (2nded.). CRC Press. p.65. ISBN 978-1-351-44995-3.Tsuchida, Masahiro; Naito, Kimiyosi; Fujii, Toru (1995). "Effects of CNBR Modification on Mode I Fracture of Epoxy Adhesives for Automotive Application". SAE Transactions. 104: 25–33. ISSN 0096-736X. JSTOR 44473201. Key specs – Type: Liquid plastic; Dry colour: Clear; Volume: 4ml; Consistency: Liquid; Curing time: N/A; Water resistant: Yes At such an affordable pric There are all kinds of different adhesives out there with different bonding strengths and applications. Some have a relatively low cohesive strength while others form a super-strong bond. Some are heat resistant, some are flexible, some are water-resistant, and so on. Within the wide range of adhesives available, there are two main umbrella categories:

If you are looking for glue, sealant or insulation for any part of your vehicle, Amazing GOOP may cover all your needs. People ask Here are the main types of plastic as well as some suggestions on what type of glue is best to use. These products are made to be tough, so removing them will not be the easiest thing to do, especially if you leave it until it hardens thoroughly. This is why you remove anything in the vicinity of your workspace you do not want glue to get on. Novolaks [ edit ] General structure of epoxyphenol novolak with n usually in the range from 0 to 4. The compound is present in the form of various constitutional isomers.Epoxy adhesives are a major part of the class of adhesives called "structural adhesives" or "engineering adhesives" (that includes polyurethane, acrylic, cyanoacrylate, and other chemistries.) These high-performance adhesives are used in the construction of aircraft, automobiles, bicycles, boats, golf clubs, skis, snowboards, and other applications where high strength bonds are required. Epoxy adhesives can be developed to suit almost any application. They can be used as adhesives for wood, metal, glass, stone, and some plastics. They can be made flexible or rigid, transparent or opaque/colored, fast setting or slow setting. Epoxy adhesives are better in heat and chemical resistance than other common adhesives. In general, epoxy adhesives cured with heat will be more heat- and chemical-resistant than those cured at room temperature. The strength of epoxy adhesives is degraded at temperatures above 350°F (177°C). [46] Sukanto, Heru; Raharjo, Wijang Wisnu; Ariawan, Dody; Triyono, Joko; Kaavesina, Mujtahid (2021-01-01). "Epoxy resins thermosetting for mechanical engineering". Open Engineering. 11 (1): 797–814. Bibcode: 2021OEng...11...78S. doi: 10.1515/eng-2021-0078. ISSN 2391-5439. S2CID 235799133. And when we say “flexible”, we don’t just mean in the sense that it can be applied to many other materials and not just plastic, but that it also features a rubber-infused formula, which means it can be used to adhere plastic elements that are required to bend. There are many different types of adhesives out there that can bond plastics and any other target material. It requires mixing two parts together, so you will need some knowledge and precision mixing and understanding the ratios

Using the UV light, the resin only takes four seconds to cure. One user found that it “took about 5 seconds to bond two pieces of plastic together. No mess and easy to use.” Once fully cured the result is a very durable repair that is waterproof, heat resistant, and can be sanded and painted. Reviewers say they get good results with this glue on laptop frames and other plastic handles or latches that need repair. One idea is to mix it in the corner of a plastic bag. You can mix it without air bubbles and when it is ready, you can cut the bag and use it as a frosting bag. People ask It can be used as a versatile gap filler, surface repairs and laminating. It can be tinted with earth pigments, cement or sand for color matching. Epoxies can also can be sanded and drilled. Ranjbar, Zahra (2009-01-01). "Optimization of a Waterborne Epoxy Coatings Formulation via Experimental Design". {{ cite journal}}: Cite journal requires |journal= ( help) Here is a list of the top plastic glues, followed by a buying guide to help you select the best plastic adhesive for your needs.Are you searching for the best plastic epoxy, then you will know how many choices you have available. To help you out a little on your search, we have selected three of the best epoxy for plastic. Tian, Xiaodong; Geng, Ye; Yin, Dongqing; Zhang, Baolong; Zhang, Yuying (2011-02-01). "Studies on the properties of a thermosetting epoxy modified with chain-extended ureas containing hydroxyl-terminated polybutadiene". Polymer Testing. 30 (1): 16–22. doi: 10.1016/j.polymertesting.2010.09.011. ISSN 0142-9418. Epoxy resins typically require a precise mix of two components which form a third chemical to get the stated properties. Depending on the properties required, the ratio may be anything from 1:1 or over 10:1, but in usually they must be mixed exactly. The final product is then a precise thermoset plastic. Until they are mixed the two elements are relatively inert, although the 'hardeners' tend to be more chemically active and should be protected from the atmosphere and moisture. The rate of the reaction can be changed by using different hardeners, which may change the nature of the final product, or by controlling the temperature.

Great Deal

Great Deal